This week, I attended Label Expo Europe in Brussels for the first time. Although I had attended Label Expo in the US several times before, I found this session much more valuable. Let me share with some of the new, exciting technologies I saw in the print on-demand color world.

|

| Guy Mikel at Label Expo Europe 2017 |

The most exciting new technology I saw at Label Expo did not involve labels; rather corrugated. Beautiful, On-Demand, Color Corrugated.

|

| Inkjet Coated Corrugated Printed with the NS Multi |

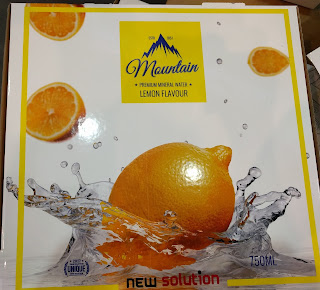

New Solution (www.newsolution.eu) was showing inkjet coated corrugated printed with the NS Multi Corrugated printer.

At approximately $100,000, this printer is not inexpensive. The NS Multi uses 5 Memjet print heads to print up to 42” wide corrugated; very quickly. Watch this corrugated printer in action:

Here is a picture for the loading table:

|

| NS Multi |

Using the inkjet coated corrugated created by New Solution, you can now produce cartons for all of your products on demand. To make this system work, you flood-coat print the boxes with the inkjet coating, then form the box, and then print. Box manufacturers should be able to produce the inkjet coated material as it’s no different than flood coat printing. Once the box is coated, the NS Multi produces great looking boxes. I was very impressed.

|

| NS Multi Printed Box |

For those regular readers to this blog, you may remember our work in print on-demand corrugated:

This new technology opens packaging to the same drivers as on-demand color label printing. With all the SKU’s, now you can produce the boxes you need, when you need them. On-demand cartons offers significant cost savings in both reducing obsolete inventory and improving processes.

In addition to the new corrugated technology, Okidata launched the new Pro1050 color LED label printer.

|

| Okidata Pro1050 |

The Pro511 uses new technology to print compared to most LED and laser printers. This technology offers better color registration and narrower/shorter labels as well as no waste of label traveling through the printer at the end of a print job.

- .83” to 4.95” Print Width

- .5” to 52” Print Length

- 6” per second

- 1200 x 1200 DPI

- 60 KG (no on-demand demonstrations at this weight)

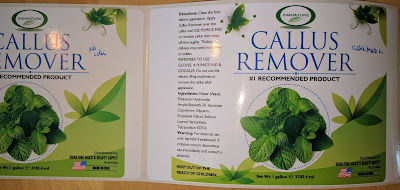

Plus this technology produces great looking blacks and even white colors on a wide variety of substrates. Notice how black is the print.

|

| Pro1050 Black On Clear Film |

|

| Pro1050 White on Clear Film |

|

| Pro1050 on Silver Metallic |

|

| Pro1050 on Antique Beer Label |

Now, very clear film, metallic, bright gloss synthetic, inexpensive films and other materials will be available for on-demand color printing. And the printer toner costs will be priced competitively to inkjet ink according to Okidata.

However, Okidata will not make this printer available in North America initially. I will keep you informed as I learn more of their plans.

Although we’ll not be able to sell the new Pro1050, we’ll start selling the new L501 as soon as it’s available approximately February 2018.

|

| L501 Color Label Printer |

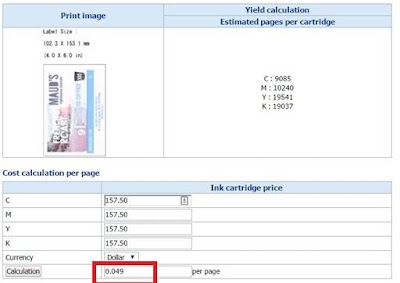

With an estimated list price of approximately $3300 (official price has not been set as yet), this 8.5” wide color label printer produces great looking labels; in both dye and pigment-based inks. The L501 offers great flexibility in printing by changing the consumable printhead. Need bright colors; use dye-based inks. Need durable prints; use pigment-based inks.

Watch the L501 print wide labels here:

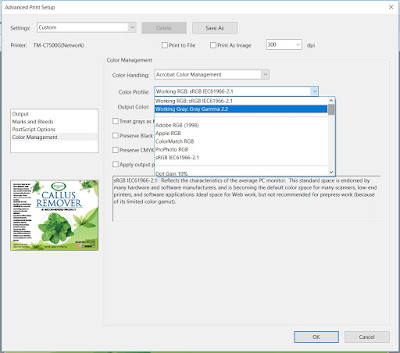

|

|

Normal mode on the left; and draft mode on the right

|

The L501 is very comparable to the LX2000; but from my perspective better design in both the hardware and software. The L501 uses a newer generation of HP print engine compared to the LX2000. I’m very hopeful for the L501 for those companies who must print wider than 4.25” labels. Compared to the LX2000 from Primera, the L501 should offer a better design, faster printing and maybe lower ink costs according to Afinia.

As the L501 gets closer to market, we’ll keep you informed on the availability of this new 8.5” wide label printer.

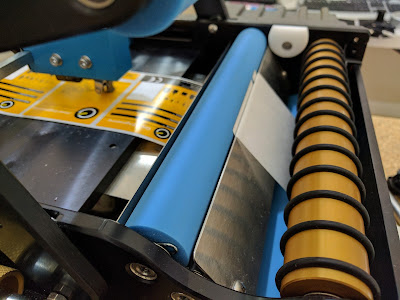

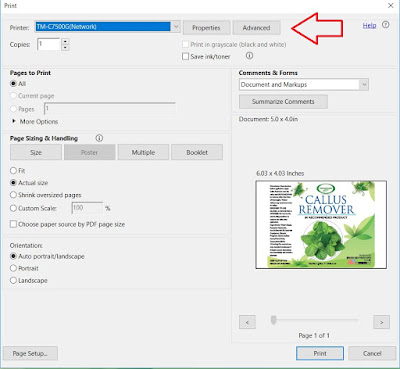

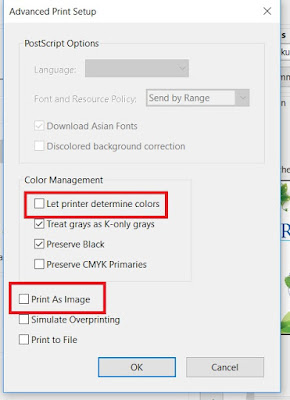

For professional printers and in-plant print shops, we saw the perfect companion device to the C7500GE at Label Expo; the Eclipse Mini Finishing Station from Impression Technology Europe:

|

| Mini Finishing Station |

At approximately $10,000, the Mini Finishing Station can laminate and die cut label up to approximately 4” wide at a price point much less expensive than other finishing stations available on the market. Most of the other finishing stations start at approximately $25,000. With the Mini, you can now print continuous labels, laminate and then die cut to the specific size you need. No more ordering a wide variety of die-cut label sizes and then printing. You can keep only one size in inventory.

Watch it run here:

The Mini uses knifes (plotter type) to cut labels and not dies. But given the mini is only 4” wide, the speed is not too bad. Not fast; but not excessively slow.

With the Mini, you can now purchase inexpensive media; and then laminate to add durability or glossy finish. And the Mini should enable you to lower your label costs. Combined with the C7500GE which offers the Wasatch RIP for better color control, the Mini makes entry into the digital printing market easy for most any professional printer. At a fraction of the cost of a digital press.

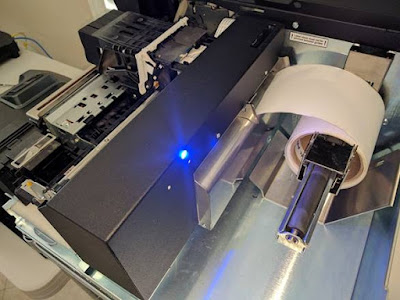

Another new hardware technology available at Label Expo came from Memjet; and both New Solutions and Trojan Label showed new versions of the above the web (media path) printhead technology. The Atom from New Solutions:

|

| Adam Color Label Printer From New Solutions |

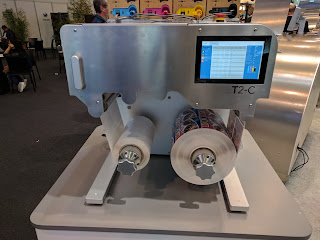

And the T2C from Trojan Label (now a part of QLS).

|

| T2C from Trojan Label |

Both of these units are high speed label presses; but in a smaller footprint. And as I understand, both use the same above the web (media path) Sirus printheads making maintenance much easier than earlier designs. I have a lot to learn about how these printers work before I comment more about the technology.

These new industrial designed color label printers will seem to produce thousands of beautiful labels. More interesting to me, is that I learned Memjet has launched a new print technology offering longer printhead life and pigment ink. Read the press release here:

By next spring, we should see pigment-based printers from Memjet OEM partners; in a variety models. With this type of great, new technology coming to market, the print on-demand color label business will continue to grow.

At the Neuralabel booth, I learned they were making a big change with their 300x color label printer.

|

| Neuralabel 300x |

According to Ken Lund, President, Neuralabel will begin selling a version of the 300x with a straight paper path. In the past, the 300x has had troubles with label media jamming as it goes around the 3 turns in the printer. By adapting the printer to use a straight paper path, the 300x should become a much better option for 8” wide label printing. Perminate printheads, fast speeds and high resolution are key capabilities of this printer if the new design can prevent jamming in the printer. Read this earlier post on the 300x here:

In addition to new hardware, I found many new types of media for print on-demand color labels.

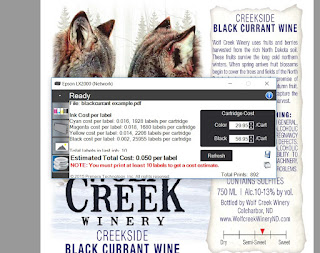

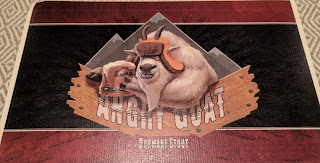

Wine labels that print great even with the low resolution C831 printer:

|

| C831 Wine Labels |

Imagine how nice these labels will print with higher resolution printers.

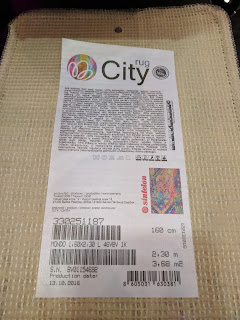

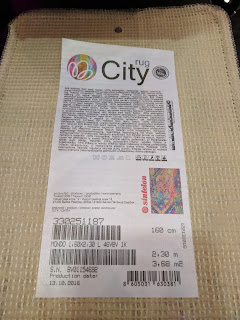

Or inkjet coated fabric labels for mattresses and carpets:

|

| Inkjet Coated Fabric Labels for Carpets |

|

| Inkjet Coated Mattress Labels |

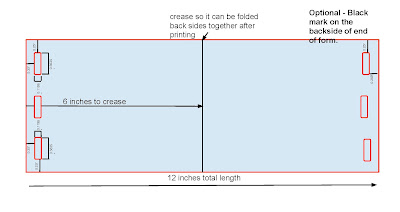

And some great new material from my friend Franz Walter Pohlhaus. Die cut, matte paper visitor badges with adhesive backing that fold at the perf to form a thicker, stiffer badge:

|

| Adhesive Backed Badges |

Inkjet coated parking stickers with on-board lamination to protect from UV rays:

|

| Inkjet Coated/Laminated Parking Stickers |

Or inkjet coated, heat-sealed paper labels that form a package after printing:

|

| Heat Sealed, On Demand, Inkjet Coated Package |

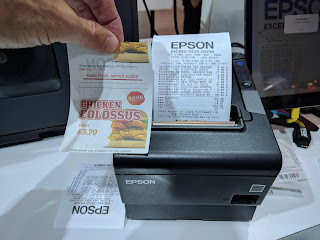

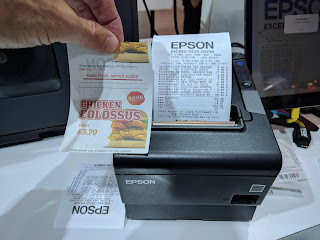

Print On-Demand Direct Thermal POS Paper

|

| Inkjet Coated POS Paper |

Watch the C7500 print the back of direct thermal POS paper here:

Overall, the trip to Label Expo was very informative; and well worth my time and money. All this new technology makes me excited by the prospects for print on-demand color labels. Contact us if we can help you with any of this new technology.

Guy Mikel

855-962-7670